The demands of showmen in all equestrian disciplines continue to grow and change, allowing for the birth and evolution of trends. And it only takes one person to step out of the safe zone for a style to spread throughout the entire industry.

Some styles come and go for various reasons, which has an effect on the people running a business based on the ever-changing realm of fashion. As some trends change, some stay the same…but others can be transformed. Morgan McCarthy-Warda and her fiancé, Michael Jennings, have found a niche in the latter which allows them to combine a fashion statement with the renewal of equipment by creating a business dyeing saddles.

Read their story, as told by Morgan, below.

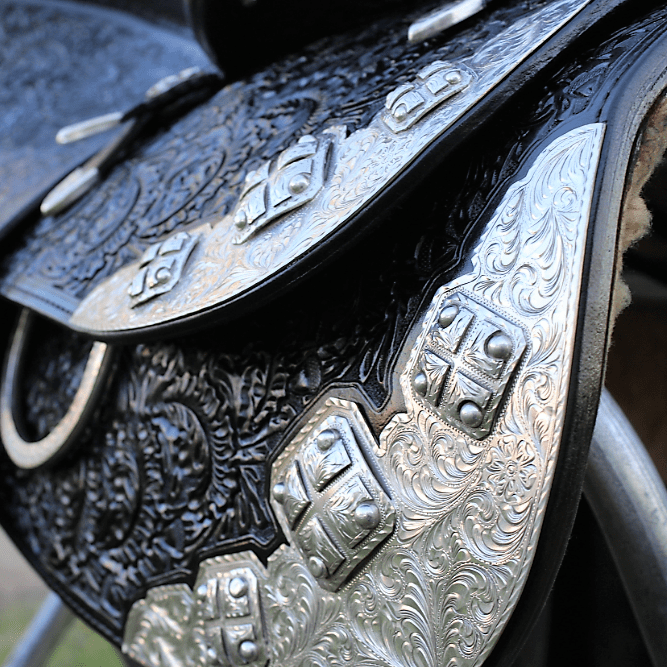

This venture began in early 2013 when I decided to create a bold horsemanship outfit that was black-on-black design. As much as we liked the look, something was missing to tie it all together. Black saddles were already an upcoming fad, and we decided to give it a try on my 20-year-old Dale Chavez. It was then that we saw the power in dyeing a saddle. What had been a well-worn, darkened leather saddle, now looked brand new and full of life.

After showing in my saddle for some time, friends started inquiring about dyeing their saddles. Michael and I started working with one saddle every few months as word spread. The entire dyeing process was done by hand with brushes and minimal tools. We were learning on the go as the saddles came in.

After showing in my saddle for some time, friends started inquiring about dyeing their saddles. Michael and I started working with one saddle every few months as word spread. The entire dyeing process was done by hand with brushes and minimal tools. We were learning on the go as the saddles came in.

Determining the average time a saddle took to complete became an important piece of information so we could accurately relay time frames to saddle owners. One thing still stands true today; each saddle has taught us something and has allowed us to grow and improve our business skills and methods.

The art of dyeing saddles is a multi-step process that can be affected by the amount of time, patience, and attention to detail that you provide. We always begin by assessing the saddle’s beginning condition. After years of practice and saddles from 7 different makers, we have learned how the leather condition will affect the way the dye will absorb. This knowledge allows us to treat each saddle as an individual with different needs throughout the process.

All silver that can be removed is taken off of the saddle to avoid contact with dye. If the decision is made to leave any silver on a saddle, it is to retain the integrity of the saddle. All remaining silver is taped for protection. Silver is always polished and restored before being reattached.

Preparing the leather for dye requires stripping the original top sealant coat off of the leather. Our saddles sit for a 24 hour period after this step to completely dry. Successfully removing this layer before dye application can affect the way color applies and absorbs. As many coats of dye that is necessary is applied, with a minimum of an hour apart. The time between the coats of color varies due to weather conditions and humidity. The number of dye coats is leather-dependent. The standard and minimum is two, but as many layers as necessary will be applied.

Preparing the leather for dye requires stripping the original top sealant coat off of the leather. Our saddles sit for a 24 hour period after this step to completely dry. Successfully removing this layer before dye application can affect the way color applies and absorbs. As many coats of dye that is necessary is applied, with a minimum of an hour apart. The time between the coats of color varies due to weather conditions and humidity. The number of dye coats is leather-dependent. The standard and minimum is two, but as many layers as necessary will be applied.

The last step for the leather is applying a new top sealant coat that secures the dye and adds the polished shine. Another 24 hour drying period is given before reattaching silver.

The last step for the leather is applying a new top sealant coat that secures the dye and adds the polished shine. Another 24 hour drying period is given before reattaching silver.

The entire process takes a week, plus a week of dry time that allows for the dye to settle in a controlled environment. Then, we go back over the leather and look for any spots that need touch ups.

Over time, the new methodology we have incorporated has allowed for the quality of our work to improve. Our dye and top coat application process have been perfected with various tools that prevents bubbles, streaking, buildup, and wasting product.

Michael and I have found a functional balance that helps us work efficiently, accomplishing multiple steps at one time. While we both have done all the steps in the process, my duties usually include the removal of silver, removing the top coat, and polishing/reattaching silver. Michael has taken on the roles of applying the dye and top coat.

Michael and I have found a functional balance that helps us work efficiently, accomplishing multiple steps at one time. While we both have done all the steps in the process, my duties usually include the removal of silver, removing the top coat, and polishing/reattaching silver. Michael has taken on the roles of applying the dye and top coat.

As a competitor myself, I understand the connection people can have to their saddles. This practice has given people a chance to affordably revitalize older or well worn show saddles instead of buying a new one. As much as we would all like to buy new, it’s not always possible. It was this realization that our name Revitalized Saddles was penned.

Even with aged saddles taking up the majority of our time, we still see our fair share of new, light oil saddles. The ratio between the two gives us some fashion insight for the industry. When dyed saddles first became popular, there was a rush of people who wanted to join the ‘in’ crowd. It was expected that like most trends, dyed saddles would fade back out and be seen less and less. Our experience has proven otherwise.

Even with aged saddles taking up the majority of our time, we still see our fair share of new, light oil saddles. The ratio between the two gives us some fashion insight for the industry. When dyed saddles first became popular, there was a rush of people who wanted to join the ‘in’ crowd. It was expected that like most trends, dyed saddles would fade back out and be seen less and less. Our experience has proven otherwise.

People are making the decision with a couple of motives in mind. A horse’s color plays a huge role in the decision to dye a saddle. If a horse is darker, some people prefer the quietness of a dark saddle. Chaps can blend in with the saddle making a cleaner line between a rider’s leg, the horse’s side, and the saddle. This can be a favorite in horsemanship.

On another note, some people want the contrast between a light color horse and a dark saddle. An example would be a black saddle on a grey horse. Complementing colors can add credibility to the overall look of horse and rider combination.

On another note, some people want the contrast between a light color horse and a dark saddle. An example would be a black saddle on a grey horse. Complementing colors can add credibility to the overall look of horse and rider combination.

Restoring the overall look of a saddle can also increase its value. We have had multiple saddles brought to our shop directly to be dyed and resold by the owner. By doing so, the owner is able to offer a saddle that has a new look – increasing its marketability.

Whatever reason a person brings a saddle to us, it’s always fun to see their reaction to the outcome. Most people are shocked and the most common response is, “It looks brand new!”

Whatever reason a person brings a saddle to us, it’s always fun to see their reaction to the outcome. Most people are shocked and the most common response is, “It looks brand new!”

After hours of work, this is the kind of reaction that we hope for. We both find time after our full-time jobs and horse shows to work on saddles, and promote Revitalized Saddles with the help of Kelsey Keathly of Norfleet Marketing, the creative mind behind our logo and advertisements.

We have taken the phrase “ride or die,” commonly used to describe someone’s go-to, favorite thing and changed it to “ride or dye,” (soon to be seen on t-shirts). Saddle dyeing has become a part of our everyday life and pushes us to better our practice so we can better service our equestrian friends.

As Revitalized Saddles approaches its 50th saddle, we are proud of the variety of equipment we have worked with including headstalls, reins, breast collars, and show halters. We offer custom designs, two-tone dye patterns, black and chocolate brown dye. The chocolate has been popular for palominos, sorrels, and liver chestnuts.

As Revitalized Saddles approaches its 50th saddle, we are proud of the variety of equipment we have worked with including headstalls, reins, breast collars, and show halters. We offer custom designs, two-tone dye patterns, black and chocolate brown dye. The chocolate has been popular for palominos, sorrels, and liver chestnuts.

The more we work with saddles, the more amazed we are at the craftsmanship that goes into them. At Revitalized Saddles, each saddle is treated like the piece of art that it is. For more information, please visit our Facebook page or email us at [email protected].